Metal forming

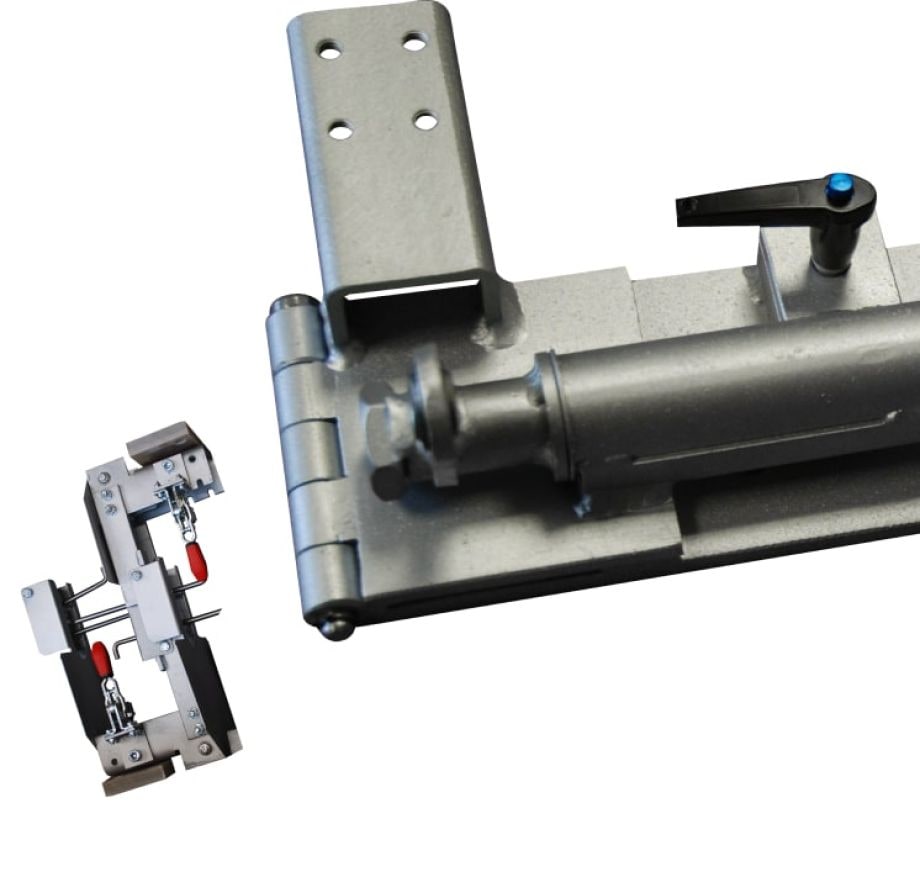

Metal forming is a process that allows for precise shaping of materials by deforming them, without removing excess material. Thanks to modern technologies and advanced devices, we provide a wide range of services, tailored to the individual needs of our customers. We specialize in processes such as stamping, bending, rolling, forging and cutting, ensuring durability and precision of execution, even in the case of the most complex elements.

Our offer also includes welding of steel structures using the TiG and MAG method in an argon shield and preparation of elements for laser or plasma burning. Thanks to our extensive machinery park, we offer cutting of sheet metal using a guillotine (up to 8 mm thick on a length of 3200 mm) and cutting with a band saw (profiles, pipes, rollers, bars up to 250x250 mm).

Bending of sheet metal elements is performed on press brakes with a table length of 3200 mm, enabling the creation of angles, channels, as well as T and U shapes. We also make comprehensive structures, such as belt and screw feeders, with the appropriate selection of drives.

Our advanced technologies allow for the production of both small and large series of elements, guaranteeing high quality, repeatability and efficiency. We also create technical documentation based on the customer's instructions, ensuring full compliance with design requirements.

We are ready to help you implement your plans.

- ul. Lipska 70B

42-700 Lubecko

Poland - +48 667 722 559

+48 605 490 990 - formako@formako.pl